home |

electronics |

toolbox |

science club |

tuxtalk |

photos |

e-cards |

online-shop

A Digital DC Power Supply (programmable bench power supply unit)

![[Illustration]](../../common/images2/article07071/ddcp6-bluedisp.jpg)

Abstract:

A good, reliable and easy to use bench power supply unit is probably the most

important and most used device in every electronic lab.

A proper electronically stabilized

bench power supply unit can easily cost over 200 Euro.

Using a clever microcontroller based design we can build a power

supply which has more features, is easy to build and and even cheaper.

_________________ _________________ _________________

|

Introduction

This bench power supply unit is less comlex than most other circuits but

has a lot more features:

- The display shows the actual measured values for voltage and current.

- The display shows the pre-set limites for voltage and current.

- Only standard components are used (no special chips).

- Only one power source is needed (no separate negative supply voltage for operational

amplifiers or control logic)

- You can completely control the power supply from your PC. You can read

current and voltages and you can set them with simple commands. This is very

useful for automated testing.

- A small button pad is available to directly enter the desired voltage and max.

current.

- It is really small but powerful.

How was it possible to remove components and add more features? The trick is to

move functionality which is normally based on analog components like operational

amplifiers into the microcontroller. In other words the complexity of the

software and algorithms is higher but hardware complexity is reduced. This

reduces the overall complexity for you as the software can just be copied.

The basic electrical design idea

Let's start with the simplest possible electronically stabilized power supply.

It consists of 2 basic parts: a transistor and a reference voltage generated

with a Z-diode.

The output voltage of this circuit is Uref - 0.7V. The 0.7V is approximately

the voltage drop between B and E on the transistor. The Z-diode and

the resistor generate a reference voltage which is stable, even if the input

fluctuates and is noisy. The transistor is needed to handle higher currents

than the Z-diode and resistor alone can provide. In this configuration the

transistor just amplifies the current. The current which the resistor and

Z-diode need to provide is the output current divided by hfe (hef is a number

which you can lookup in the datasheet of the transistor).

What are the problems with this circuit?

- The transistor will die when there is a short circuit on the output.

- It provides only a fixed output voltage.

These are quite severe limitations which make this circuit unusable but this

circuit is

still the basic building block of all electronically regulated power supplies.

To overcome those problems you need

some "intelligence" which will regulate the

current on the output and a variable reference voltage. That's all (... and

this makes the circuit much more complex).

For the last few decades people have used operational amplifiers to provide this

intelligence. Operational amplifiers can basically be used as analog calculators to

add, subtract, multiply or logically "or" voltages and currents.

Today microcontrollers are so fast that all this can easily be done in software.

The beauty is that you get as a side effect a voltmeter and an amperemeter

for free. The control loop in the microcontrollers has to know voltage and

current values anyhow. You just need to display it.

What we need from the microcontroller are:

- A AD-converter to measure voltage

and current all the time

- A DA-converter to send commands to our power transistor (provide the

reference voltage)

The problem is that the DA-converter needs to be very fast. If there is a short

circuit detected on the output then we must immediately reduce the voltage

on the basis of the transistor otherwise it will die. Fast means within

milliseconds (as fast as an operational amplifier).

The ATmega8 has an AD-converter which is more than fast enough but it has

at first glance no DA-converter. It is possible to use pulse width modulation

and an analog low pass filter to get an DA-converter but this is much too slow

to implement the short circuit protection in software. How to build a fast

DA-converter?

The R-2R ladder

There are many ways to build a digital to analog converter but we need a

fast and cheap one which can easily interface to our microcontroller.

There is a DA-converter circuit known as "R-2R ladder". It consists of resistors

and switches only. There are two types of resistors. One with R and one

with twice the value of R.

The above shows a 3 bit R2R-DA-converter. The control logic moves the switches

between GND and Vcc. A digital "one" connects the switch to Vcc and a digital

"zero"

to GND. What does this circuit do? It provides voltages in steps of Vcc/8.

In general the output voltage is Z * (Vcc/(Zmax+1) where Z is the digital

number. In the case of a 3 bit AD converter this is: 0-7.

The inner resistance of the circuit as seen from the output is R.

Instead of using separate switches we can connect the R-2R ladder to the

microcontroller output lines. A output pin of the ATmega8 can provide

about 10mA but at this current you will notice already a voltage drop. We would

like to use the full output range from 0-5V in other words the load on the output should

be less than 1mA. We build a R-2R ladder with 5K and 10K

resistors.

The AD-converter of the ATmega8 has a resolution of 10bit. To use the resolution

completely we need also 10bit for the DA-converter.

For this we need 10 output pins which are not used by anything else. This is a little

challenge as we would also like to have a keyboard, LCD display and an I2C serial

interface to the PC. The ATmega8 is quite good. It just fits.

A more detailed design

So here is now a more detailed design of the above circuit.

I don't want to

disappoint you but it is unfortunately still a circuit which will not be usable.

However it very good to understand the idea which is behind the real circuit.

So what is wrong with this circuit? There are mainly two things:

- The DAC (digital to analog converter) can not provide the current to drive

the power transistor

- The microcontroller operates at 5V so the maximum output of the DAC is 5V

which means that the maximum output voltage behind the power transistor will be

5-0.7=4.3V .

To fix this we must add amplifiers for current and voltage.

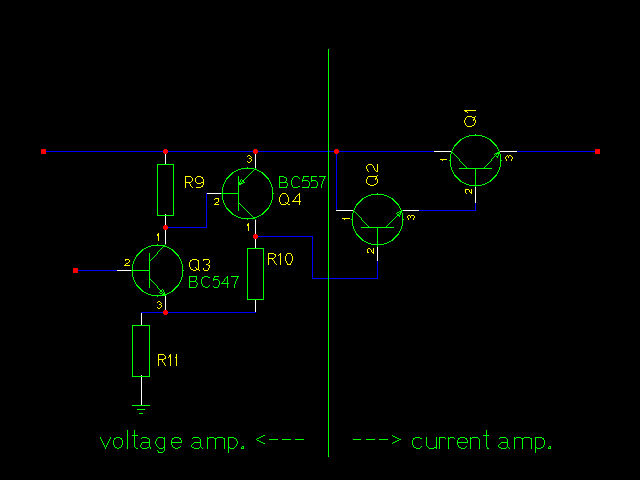

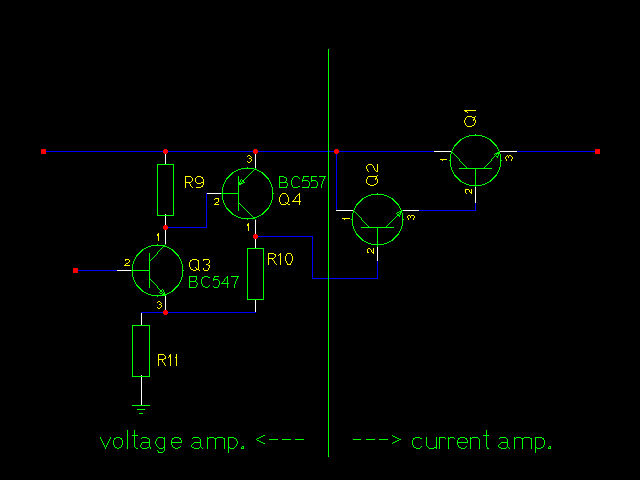

Adding an amplifer stage to the DAC

When adding amplifiers we must keep in mind that those must work with large

signals. Most amplifier designs (e.g for audio) are done under the assumption

that the signals will be small compared to the supply voltage. So forget all the

classic books about transistor amplifier design.

We could use operational amplifiers but those would require extra positive and

negative supply voltages which we want to avoid.

There is also the additional requirement that the amplifier must go from zero

voltage to a stable state without generating any output peek. In other

words there must not be any short oscillation or output peek when you switch

on the power supply.

What to do? Well this is not an easy task at all and requires some experience.

Have a look at the picture below. It shows an amplifier stage which is

suitable for this purpose.

We start with the power transistor. We use a BD245 (Q1). According to the datasheet

this transistor has

a hfe=20 at 3A output. It will therefore draw about 150mA on the basis.

To amplify the current we use

a configuration known as "Darlington transistor". For this we put a medium power

transistor

in front. Those have typically a hfe value of 50-100. This will reduce the current needed to

less than 3mA (150mA / 50).

3mA are manageable with small signal transistors like BC547/BC557. Those

small signal transistors are then very good for building a voltage amplifier.

For 30V output we must at least amplify the 5V from the DAC by a factor of 6.

For this we combine a PNP and an NPN transistor as shown below. The voltage amplification

factor of this circuit is:

Vampl= (R10 + R11)/R11

The power supply shall be

available in 2 version: Max 30 output and max 22V output. A combination of 1K

and 6.8K gives a factor of 7.8 which is good for the 30V version and has some

room for possible losses due to higher currents (our formula is linear. The reality

is non-linear). For the 22V

version we use 1K and 4.7K.

The inner resistance of the circuit as seen on the Basis of BC547 is:

Rin=hfe1 * S1 * R11 * R9 = 100 * 50 * 1K * 47K = 235 MOhm

- hfe is about 100 to 200 for a BC547 transistor

- S is the slope of the amplification curve of a transistor and is

about 50 [unit=1/Ohm]

This is more than high enough for the connection to our DAC which has a inner resistance of 5K.

The inner equivalent output resistance is:

Rout= (R10 + R11) / (S1 + S2 * R9 * R11) = about 2 Ohm

Low enough to drive the following transistor Q2.

R9 ties the basis of BC557 to

the emitter which means "off" for the transistor until the DAC and BC547 come up.

R11 and R10 tie the Basis of Q2 initially to ground which shuts the output

darlington stage down.

In other words every component in this amplifier stage is initially off.

This means we will not get from those transistors any oscillations or output

peeks at power on or power off. A very important point. I have seen expensive

industrial power supplies which produced a voltage peek at power off. Such a

power supply is definitly to be avoided as it can easily kill sensitive

circuits.

The limits

>From previous experience I know that most readers would like to

"customize" the circuit a bit. Here is a list of hardware limits

and how to overcome them:

BD245B: 10A 80W. The 80W are however at a temperature of 25'C

In other words add a safety margin and calculate with 60W-70W:

(Max input voltage * Max current) < 65W

You can add a second BD245B to go up to 120W. To ensure

that the current distributes equally add a 0.22 Ohm resistor

into the Emitter line of each BD245B.

The same circuit and board can be used. Mount the transistors

on a proper aluminum cooler and connect them with short

wires to the board. The amplifer can drive a second power transitor

(that's the maximum) but you might need to adjust the

amplification factor.

Current measurement shunt:

We use a 0.5 Ohm resistor with 6W. This is good enough

for about 3A of output (Iout^2 * 0.50 <= 6W). Use a resistor

with more watts for higher currents.

Power sources

You can either use a transformer, rectifier and big capacitors or

you can try to get a 32/24V laptop power supply.

I went for the later option. Those laptop power supply "bricks" are

sometimes sold very cheap (over stock) and some of them provide

70W at 24V or even 32V DC.

Most people will probably go for a transformer because those are

very easy to get.

22V 2.5A version: you need a 18V 3A transformer, a rectifier

and a 2200uF or 3300uF capacitor. (reason: 18 * 1.4 = 25V)

30V 2A version: you need a 24V 2.5A transformer, a rectifier and

a 2200uF or 3300uF capacitor. (reason: 24 * 1.4 = 33.6V)

It does not harm to buy a transformer which can provide more ampere.

A power diodes bridge with 4 diodes which are specified for a

low volatage drop (e.g BYV29-500) gives a good

rectifier.

You can also

use a "heavier" transformer.

Check your circuit for proper insulation. Make sure that it is not possible to

touch any part that may carry 110V/230V even when the case is open.

Connect all metal parts of the chassis to earth (not to GND of the circuit).

Other voltages and current limits

The two provided configurations are 22V 2.5A and 30V 2A. If you want

to build a version with other (lower) output voltages or current limits

then just edit the hardware_settings.h file.

Example: To build a 18V 2.5A version you just edit the hardware_settings.h

file and change the maximum output voltage to 18V.

You can then use a 20V 2.5A power source.

Example: To build a 18V 1.5A version you just edit the hardware_settings.h

file and change the maximum output voltage to 18V and the max. current to

1.5A.

You can then use a 20V 1.5A power source.

Testing

The last component to solder to the board should be the microcontroller.

Before you insert it I would recommend to do some basic hardware tests:

Test1:

Connect some power supply (at least 10V) to the power input of the circuit and

check that you get 5V DC behind the voltage regulator.

Test2: Measure the output voltage. It should be 0V (or near zero, e.g 0.15V, and

it will go to zero if you put a "load" of 2K to 5K on the output.)

Test3: Connect pin 7 and pin 26 on the microcontroller with a wire (solder

a temporary wire connection which you remove before you add later on the

microcontroller on the board). You should get on the output a couple of

volts less than what is used at DC input. Remove the wire and the output

should go back to zero. Be sure to not cause any short circuit on the output.

Solder the microcontroller to the board and load the LCD test software by running the

commands in the directory of the unpacked digitaldcpower tar.gz package.

make test_lcd.hex

make load_test_lcd

You should see "ok works" on the display.

Now you can load the final software as described above.

A word of warning for further testing with the final software: Be careful with short

circuits until you have tested the current limitation function. A save way to

test the current limitation is to use a low Ohm resistor, e.g a car bulb.

Set a low current limit, e.g 30mA at 10V. You should see the voltage

go down immediately

to almost zero once you connect the bulb on the output. There is still a fault

in the circuit if it does not go down. The car bulb will protect the power

supply circuit even if there is a fault as it is not a full short circuit.

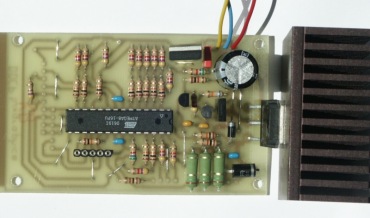

The software

This section will give you insights as to how the software

works and you can use the knowledge to do modifications.

However be aware that the short circuit protection is also only

software. If you make a mistake somewhere then this protection

may not work. If you then cause a short circuit on the output

your hardware may go off in a cloud of smoke. To avoid this

you should use a 12V car bulb (see above) to test the short circuit

protection.

Now a bit about the software structure.

First look at the main program (file main.c, download at the end of this

article) you will see

that there are only a few lines of initialization code executed

at power on and then the software enters an endless loop.

There are really 2 endless loops in this software.

One is the main loop ("while(1){ ...}" in file main.c) and the

other one is the periodic interrupt from the Analog the Digital

Converter (function "ISR(ADC_vect){...}" in file analog.c).

During initialization the interrupt is configured to execute every

100μ Sec. All functions and code that is executed runs in

the context of one of those tasks (task the name for a process

or thread of execution in a real time OS, so I use this word here even if

there is no OS).

![[priorities]](../../common/images2/article07071/tasks.gif)

The interrupt task can stop the execution of the main loop at

any time. It will then execute without being interrupted and

then execution continues again in the main loop at the place

where it was interrupted. This has two consequences:

- The code in the interrupt must not be too long as it must

finish before the next interrupt comes. What counts here are

the amount of instructions in machine code. A mathematical

formula, which can be written as just one line of C-code may

result in hundreds of lines of machine code.

- Variables that you share between interrupt code and code

in the main task may suddenly change in the middle of

execution. This is also valid when you hand more than one

byte of data from the interrupt to the main task. The copying of two

bytes will require more than one instruction and then it can

happen that the first byte is copied before the interrupt

while the second byte is copied after the interrupt. What to

do? In most cases it is not a problem because the measurement

results from the ADC will not differ too much between two

interrupts. In cases where you can not afford this type of

occasional fault (it may happen only once every hour) you

have to use a flag which you can check to see if your code

was interrupted during the copying.

All this means that complex things like updating of the

display, checking of push buttons, conversion of ampere and

volt values to internal units etc ... must be done in the main

task. In the interrupt we execute only things that are time

critical: Current and voltage control, overload protection and

setting of the DAC. To avoid complex mathematics all

calculations in the interrupt are done in ADC units. That is

the same units that the ADC produces (integer values from

0...1023).

Here is the exact logical flow of operations that we do in the

main task:

1) Copy the latest ADC results from the interrupt task

2) Convert them into display values (ampere and volt)

3) Convert the wanted ampere and volt values (what the user has set)

to internal equivalent ADC values

4) Copy the wanted equivalent ADC values to variables such that

the interrupt task can use them.

5) Clear the LCD display

6) Convert the numbers which we want to display on the LCD into

strings.

7) Write voltage values to the display.

8) Check if the interrupt task regulates currently voltage or current

(current limitation active)

9) If voltage is the limiting factor then write an arrow behind

voltage on the display

10) Write ampere values to the display

11) Check if the interrupt task regulates currently voltage or current

(current limitation active)

12) If current is the limiting factor then write an arrow behind

current on the display

13) Check if a button was pressed. If not wait 100ms and check again.

If a button was pressed then wait 200ms. This is to have a good

response of the buttons and not too fast scrolling if they are

permanently pressed.

14) Go to step 1).

The interrupt task is much simpler:

1) Copy the results from the ADC to variables

2) Toggle the ADC measurement channel between current and voltage

3) Check if excessive current is measured. If so set the DAC immediately

to a low value (It does not have to be zero since the voltage

amplifier circuit works only from 0.6V on (0.6 volt input

produce still 0 volt output)).

4) Check if voltage or current needs to be regulated

5) Check if the DAC (digital to analog converter) needs updating

according to the decision from 4).

This is the basic idea of the software. I will also explain

what you find in which files and then you should be able to

understand the code (given that you are familiar with C).

Software: Which file contains what

main.c -- this file contains the main program. All initialization is

done from here.here. The main loop is also implemented here.

analog.c -- the analog to digital converter and everything that

runs in the context of the interrupt task can be found here.

dac.c -- the digital to analog converter. Initialized from ddcp.c but

used only from analog.c

kbd.c -- the keyboard code

lcd.c -- the LCD driver. This is a special version which will not need

the rw pin of the display. It uses instead an internal timer

which should be long enough for the display to finish its task.

Loading and using the software

Now you want to know how the use the software and how to load

it.

Unpack the digitaldcpower tar.gz package and "cd" into the directory

that is created.

Edit the file hardware_settings.h and adjust it according to the hardware.

Here you can also do calibrations of voltmeter and amperemeter. The file

is well commented.

gedit hardware_settings.h

Connect the programmer cable and power on the circuit.

Then run:

make wrfuse4mhz

This will set the clock frequency of the microcontroller to 4MHz. The

software is designed for this frequency.

make

This will compile the software.

make load

This will load the software.

Control of the power supply unit from any PC (Win, Linux, Mac,...)

This lab/bench power supply can be controlled not only locally from the front

pannel but also via command.

That is: You can optionally connect a computer and give a command to say "produce 6V"

and the power supply will change to 6V. A really cool feature for automated

testing.

To remotely control the power supply via commands we will use

again I2C communication (see also A simple digital thermometer). I2C communication is a bit

slow but we do not send long commands. A command to set the

voltage could e.g be as short as "u=12". This is still human

readable and understandable but only a few bytes long.

The software to do this remote control has by now been ported

to Linux, Windows, Mac OS X and Solaris. It is probably

quite easy to port this code to even more operating systems.

How control via I2C works

I2C is a protocol over a two wire bus. One line on the bus

carries the clock (SCL) and the other the data (SDA). This has the big

advantage that you do not need a precise synchronous clock

signal. The timing is not so important for I2C therefore it is very

easy to implement in a simple user space program (no special

kernel module). For the physical interface we use again the

rs232 modem control lines. USB is also possible to use via a

USB to serial converter. The new Apple Macs have e.g no rs232

but because I2C is not sensitive to timing it is

possible to use adapter cables such as the Prolific PL-2303

(there are some links to USB adapters in the software for this

article under other_OS/macOSX/README.txt, see download at the

end of this article).

The program to send commands to our DC power supply is a

simple command line based program called i2ctalk. It is

available in source code and as precompiled binary for Linux, Solaris,

Mac OSX and Windows. You use it like this:

I2C commands for the DC power supply:

=====================================

# set Imax to 0.20A:

i2ctalk i=20

# get current I value:

i2ctalk i

# store current settings

i2ctalk s

# set Umax to 2.1V:

i2ctalk u=21

# get current voltage value:

i2ctalk u

You can enhance the program and build a fancy graphical

application if you want. I have just tired to keep it as simple

as possible.

The buttons

The power supply has 4 button for local control of voltage and max. current.

The 5-th button is to store the settings permanently in an eeprom such that

it will come on with identical settings the next time you power it on.

![[buttons]](../../common/images2/article07071/buttons.gif)

The local control button pad.

With U+ you can increase the voltage and with U- you decrease it. When you

hold the button then it will step and after a while "run" faster to make

it easy to change the voltage in large steps. The I+ and I- buttons work

the same way.

The display

This is how the display looks like:

![[display]](../../common/images2/article07071/display.png)

The fields in the LCD display area. The real measured

values and the set values are always shown at the same time.

The arrow on the right indicates that currently the configured voltage

is the limiting factor. Should a short circuit occur on the output or

the connected device draws more current then the arrow will flip to the

bottom line and indicate that the configured max. current has become the limiting

factor.

Blocking HF interference

DC-motors without filters and other devices containing large coils

can generate strong high frequency signals. Those can potentially

interfere with the LCD display electronics.

The result can be funny characters on the display.

The microcontroller itself is not so sensitive as it is mostly self contained.

The interference depends also to a large degree on how the internal wiring inside

the case of the power supply is done. Longer cables between display and

circuit board act as antennas which can easily pick-up HF signals. In any case

the best solution is to block HF signals directly at the front connector

of the power supply.

Solder a ceramic capacitor in the range of 10nF to 100nF directly

behind front connectors:

![[block HF signals]](../../common/images2/article07071/ddcp9.jpg)

A ceramic capacitor between the power output connectors to

block HF-signals from coming into the power supply.

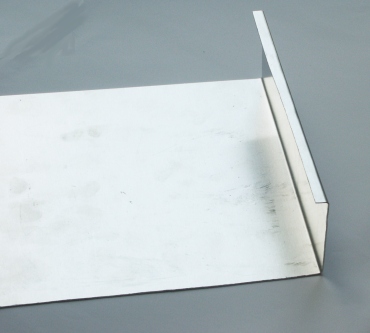

Some pictures and ideas

Here are some pictures from the power supply(s) which I have build.

Pictures are sometimes much better than long description especially when

it comes to hardware and mechanical parts.

You can build a simple but professionally looking case from an

aluminum sheet and two wooden boards.

Just bend the aluminum twice. This is easy to do even without

professional equipment.

Mark the positions of the push buttons on the case before you

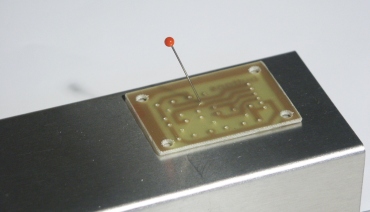

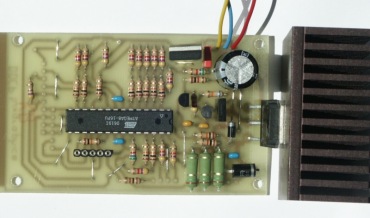

solder the buttons onto the board. This makes it easy to drill the

holes at the right position.

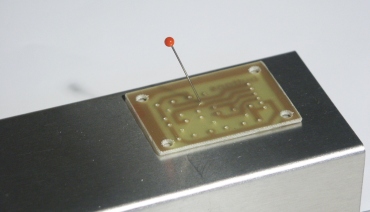

The circuit. Very small but with more features and more powerful than many

other power supply circuits.

The final power supply unit. With a green display.

... and with a blue display. It looks cool and is very small. Just 4.5cm high. Incredible

what such a small power supply can do. Blue displays are bit difficult to

photograph.

It looks even better in reality than here on the photo.

How it looks inside. I used an old 24V 3A laptop power supply "brick"

as power source. They are very compact and don't need additional rectifiers

or capacitors.

|

Have fun! I am sure you will like this power supply unit. I use it a lot

and every day.

References/Download

- Download page for this article

(firmware updates and corrections will also be available from here).

- Datasheet for the ATmega8: go to http://www.atmel.com/

and select products->Microcontrollers ->AVR-8 bit

RISC->Documentation->datasheets

- Tuxgraphics electronics section, a collection of all articles in this series.

- Tuxgraphics

online shop, You can order this power supply unit as a kit from here.

The kit includes not only the parts but also additional documentation

and the circuit diagram.

© Guido Socher, tuxgraphics.org

2008-05-18, generated by tuxgrparser version 2.55

![[Illustration]](../../common/images2/article07071/ddcp6-bluedisp.jpg)

![[priorities]](../../common/images2/article07071/tasks.gif)

![[buttons]](../../common/images2/article07071/buttons.gif)

![[display]](../../common/images2/article07071/display.png)

![[block HF signals]](../../common/images2/article07071/ddcp9.jpg)